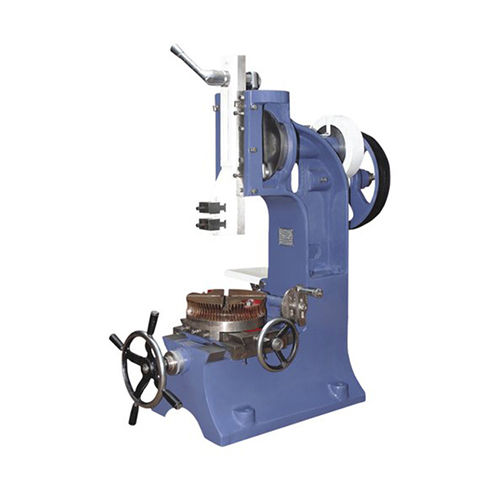

203mm Heavy Duty Slotting Machine

Price 150000 INR/ Piece

203mm Heavy Duty Slotting Machine Specification

- Product Type

- Other

- Technology

- CNC

- Power Source

- Electricity

- Operating Type

- Manual

- Surface Treatment

- Coated

- Dimension (L*W*H)

- 60*25*65 Inch (in)

- Weight (kg)

- 700 Kilograms (kg)

- Color

- green

- Warranty

- yes

- Production Capacity

- 5 Pcs/min

- Usage & Applications

- Industrial

203mm Heavy Duty Slotting Machine Trade Information

- Minimum Order Quantity

- 1 Inch

- Supply Ability

- 100 Inches Per Month

- Delivery Time

- 20 Days

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- Gujarat

About 203mm Heavy Duty Slotting Machine

A 203mm heavy duty slotting machine is a specialized industrial equipment designed to create precise slots or keyways in metal components. The "203mm" refers to the maximum width of the slot it can cut. These machines are typically used in industries like manufacturing, automotive, and aerospace where high-precision and durability are essential.

Key Features and Functions:

- Heavy-Duty Construction: Built to withstand the rigors of continuous operation, these machines often feature robust frames, sturdy components, and high-quality materials.

- Precise Cutting: Equipped with advanced cutting tools and mechanisms, they can produce slots with exceptional accuracy and consistency.

- Versatility: Many models offer adjustable settings to accommodate various slot depths, widths, and shapes, making them adaptable to different applications.

- Efficient Operation: Features like automatic feed systems and rapid tool changes can significantly improve productivity.

- Safety Mechanisms: Built-in safety features, such as emergency stops and guards, help protect operators and prevent accidents.

Typical Applications:

- Keyways: Creating keyways in shafts for connecting pulleys, gears, and other rotating components.

- Slots for Pins and Dowels: Producing slots to accommodate pins, dowels, or other fasteners.

- Grooves for Seals: Machining grooves for sealing elements like O-rings and gaskets.

- Component Assembly: Preparing components for assembly by creating precise slots for interlocking parts.

Additional Considerations:

- Power Source: Most heavy-duty slotting machines are powered by electricity, but some may use hydraulic or pneumatic systems.

- Maintenance: Regular maintenance is crucial for ensuring optimal performance and longevity. This includes cleaning, lubrication, and periodic inspections.

- Safety Training: Operators should receive proper training on the machine's operation, safety procedures, and emergency response.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Slotting Machines Category

250mm Heavy Duty Slotting Machine

Price 178000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Industrial

Operating Type : Manual

Surface Treatment : Coated

Product Type : Other

180mm Heavy Duty Slotting Machine

Price 110100 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : industrial

Operating Type : Manual

Surface Treatment : Coated

Product Type : Other

Heavy Duty Slotting Machine

Price 120000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Heavy Duty Slotting Machine

Operating Type : Automatic

405mm Heavy Duty Slotting Machine

Price 375000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Industrial

Operating Type : Manual

Surface Treatment : Coated

Product Type : Other, Slotting Machine

GST : 24ATXPP8718L1ZO

|

YOGESH ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry